Sheet metal fabrication

Precision Engineered. Expertly Fabricated.

About Us

About VJS

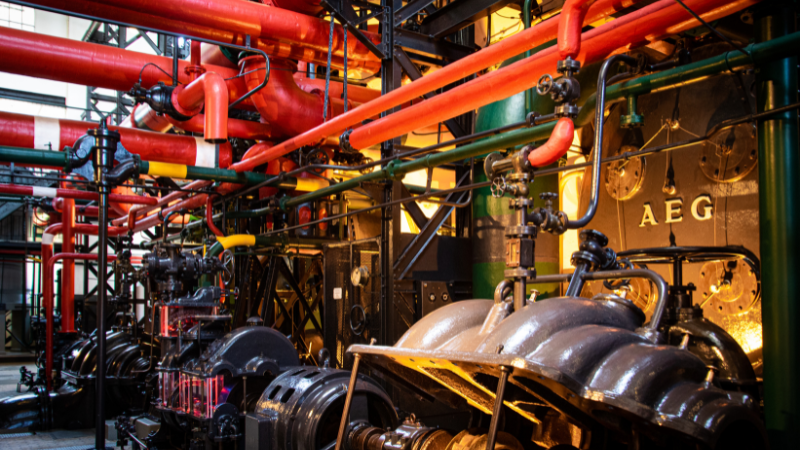

Founded in 1990 by the visionary leadership Mr. M. B. Sadhashivaiah, VJS Auto Components began its legacy as Surface Treatment Systems, with a core focus on powder coating solutions. Over time, the company strategically diversified into the design and manufacturing of metal-formed products and welded assemblies, establishing a strong reputation for precision and performance.

A major milestone came in 2024, when Surface Treatment Systems – Unit 2 underwent a strategic transformation, emerging as VJS Auto Components Private Limited. This rebranding signified more than a name change—it was a bold statement of expanded capabilities, forward-thinking leadership, and a renewed commitment to delivering excellence.

Today, VJS Auto Components stands at the forefront of engineering-driven manufacturing, delivering world-class solutions across diverse sectors. Powered by a strong foundation in engineering innovation, lean processes, and stringent quality standards, VJS is trusted by partners to deliver value, speed, and reliability.

VJS is more than a manufacturer—it’s a technology-driven partner helping shape the future of industries. With visionary leadership and a relentless focus on agility and innovation, VJS Auto Components continues to evolve, empower, and excel.

Vision

“To be the leading provider of innovative, sustainable, and high-quality sheet metal fabrication and assembly solutions across the automobile, agricultural, infrastructure, railways, renewable energy and otherengineering industries, recognized for our commitment to excellence and our ability to exceed customer expectations.“.

Mission

“Our mission is to deliver top-tier sheet metal fabrication and assembly services. We achieve this through a customer-focused mindset, and a dedication to sustainability and continuous improvement. Our goal is to provide reliable, cost-effective, and innovative solutions that create value for our clients and drive industry growth.”

Core Values

- Customer Focus: Our clients’ needs drive our actions. We strive to exceed expectations and build longlasting

relationships. - Quality: We uphold the highest standards of craftsm

anship and precision in every component we produce,

guaranteeing reliability and durability. - Innovation: We constantly seek new and improved

methods to refine our metal forming processes, ensuri

ng we stay ahead in a competitive market. - Sustainability: We commit to environmentally friend

ly practices, reducing waste and conserving resources

to protect our planet. - Integrity: We operate with honesty, transparency, a

nd accountability in all our business dealings.

History

VJS Auto Components Private Limited

Founded in 1990 by the visionary leadership Mr. M. B. Sadhashivaiah, VJS Auto Components began its legacy as Surface Treatment Systems, with a core focus on powder coating solutions. Over time, the company strategically diversified into the design and manufacturing of metal-formed products and welded assemblies, establishing a strong reputation for precision and performance.

A major milestone came in 2024, when Surface Treatment Systems – Unit 2 underwent a strategic transformation, emerging as VJS Auto Components Private Limited. This rebranding signified more than a name change—it was a bold statement of expanded capabilities, forward-thinking leadership, and a renewed commitment to delivering excellence.

Today, VJS Auto Components stands at the forefront of engineering-driven manufacturing, delivering world-class solutions across diverse sectors. Powered by a strong foundation in engineering innovation, lean processes, and stringent quality standards, VJS is trusted by partners to deliver value, speed, and reliability.

VJS is more than a manufacturer—it’s a technology-driven partner helping shape the future of industries. With visionary leadership and a relentless focus on agility and innovation, VJS Auto Components continues to evolve, empower, and excel.

Executive Team

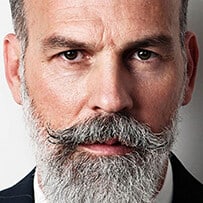

Mr. M.B. Sadashivaiah

Managing Director

With over four decades of leadership in global manufacturing, our Managing Director is the driving force behind VJS Auto Components’ strategic growth and transformation. Their vision blends operational excellence with innovation, building a culture rooted in trust, agility, and continuous improvement.

As the strategic architect of VJS’s evolution, they have successfully expanded the company into new markets, fostered long-standing customer partnerships, and ensured our operations remain future-ready in a dynamic global landscape. Through their commitment to people, purpose, and progress, the Managing Director empowers teams and strengthens VJS’s position as a trusted partner worldwide.

Mr. Vinay Sadashivaiah

Director

A young and dynamic leader, our director brings energy, insight, and execution strength to the heart of VJS Auto Components. With a hands-on mindset and a deep understanding of governance and growth strategy, they ensure that every decision aligns with our long-term vision and stakeholder expectations.

Their leadership helps shape company policies, drive cross-functional collaboration, and integrate emerging opportunities into core operations. the Director plays a vital role in building resilience, transparency, and sustainable value creation.

Mr. N A Sudhakar

Chief Executive Officer (CEO)

With over 36 years of global leadership across manufacturing, strategy, and operational excellence, our CEO leads VJS Auto Components with a clear purpose to create value that lasts—through people, partnerships, and progress.

As a Certified Independent Director and Sustainability Champion, their leadership is grounded in empathy, trust, and a commitment to doing what’s right for employees, customers, and communities. They believe in empowering teams, listening closely to customer needs, and shaping a workplace where innovation thrives and everyone grows together from the shop floor to the boardroom, the CEO ensures that VJS remains future-ready, socially responsible, and human at heart.

CAPABILITIES

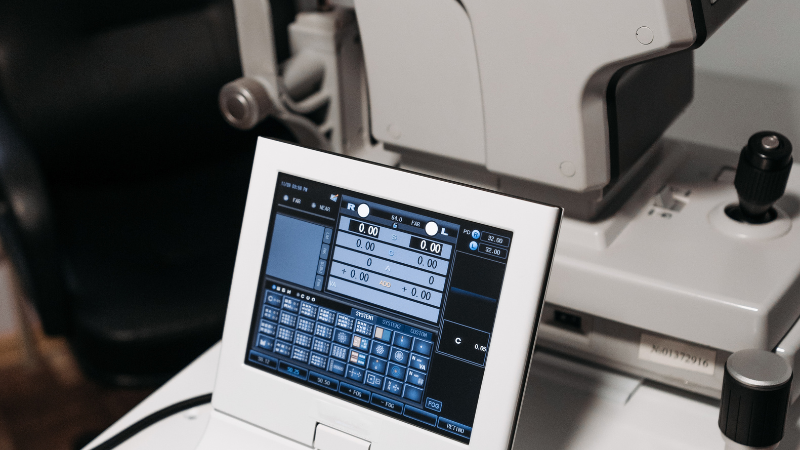

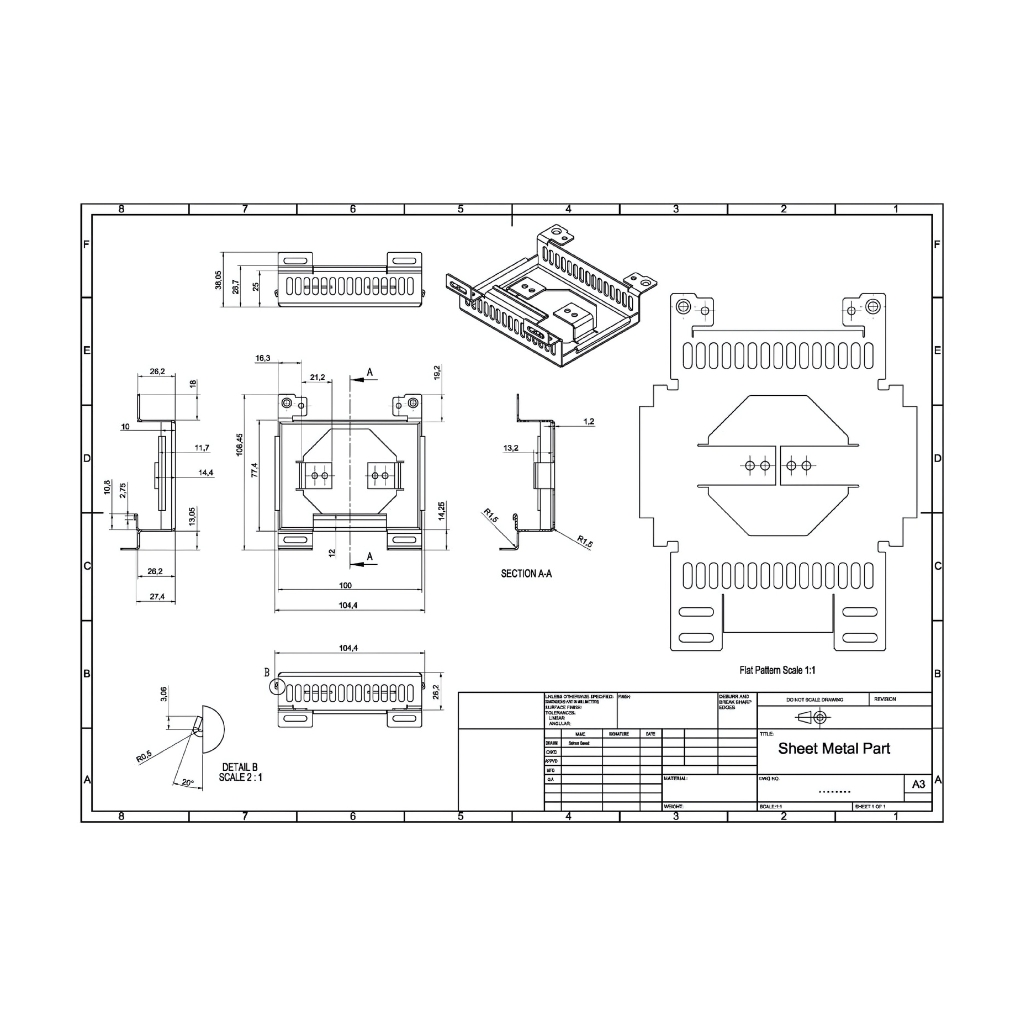

Tool Design

Our in-house Tool Design Division is a strategic asset that powers precision, performance, and productivity across the metal forming and fabrication value chain.

our in-house Tool Design Division is a strategic asset that powers precision, performance, and productivity across the metal forming and fabrication value chain.

Advanced Metal Forming Tooling: Expertise in designing progressive, compound, and transfer dies tailored for complex geometries, high-strength materials, and tight tolerances

Fabrication and Assembly Jigs/Fixtures: Custom fixture design for welding, bending, trimming, and component location—ensuring consistency, ergonomics, and cycle time optimization

3D Design Integration: Proficient use of cutting-edge CAD/CAM platforms (e.g., AutoCAD, CATIA, SolidWorks) to simulate manufacturability and proactively reduce iterations

DFM-Driven Approach: Designs are developed with manufacturability, maintainability, and cost-efficiency at the core—ensuring smooth downstream operations

Our tool design capability is more than just technical excellence—it’s about building the foundation for flawless manufacturing. Whether it’s a high-volume stamping tool or a specialized fabrication fixture, we engineer with purpose and precision.

Engineering

our engineering function is the backbone of innovation—merging precision, agility, and sustainable design thinking to deliver intelligent solutions across metal forming, fabrication, and assembly.

Process Engineering: Proven expertise in developing robust metal component designs with manufacturability and performance built-in, Cross-functional process planning using APQP, PFMEA, and control plan integration

Design for Manufacturability (DFM) & Design for Assembly (DFA): Early-stage engineering support to optimize cost, quality, and tooling performance, Value engineering and re-engineering to enhance part functionality and reduce waste

Reverse Engineering & Prototyping: Rapid development cycles for part reverse engineering, feasibility assessment, and first-article validation, Close integration with toolroom and production for seamless prototype-to-production transitions

Our engineering team doesn’t just deliver designs—they build future-ready, customer-aligned, and sustainability-conscious solutions that power global competitiveness.

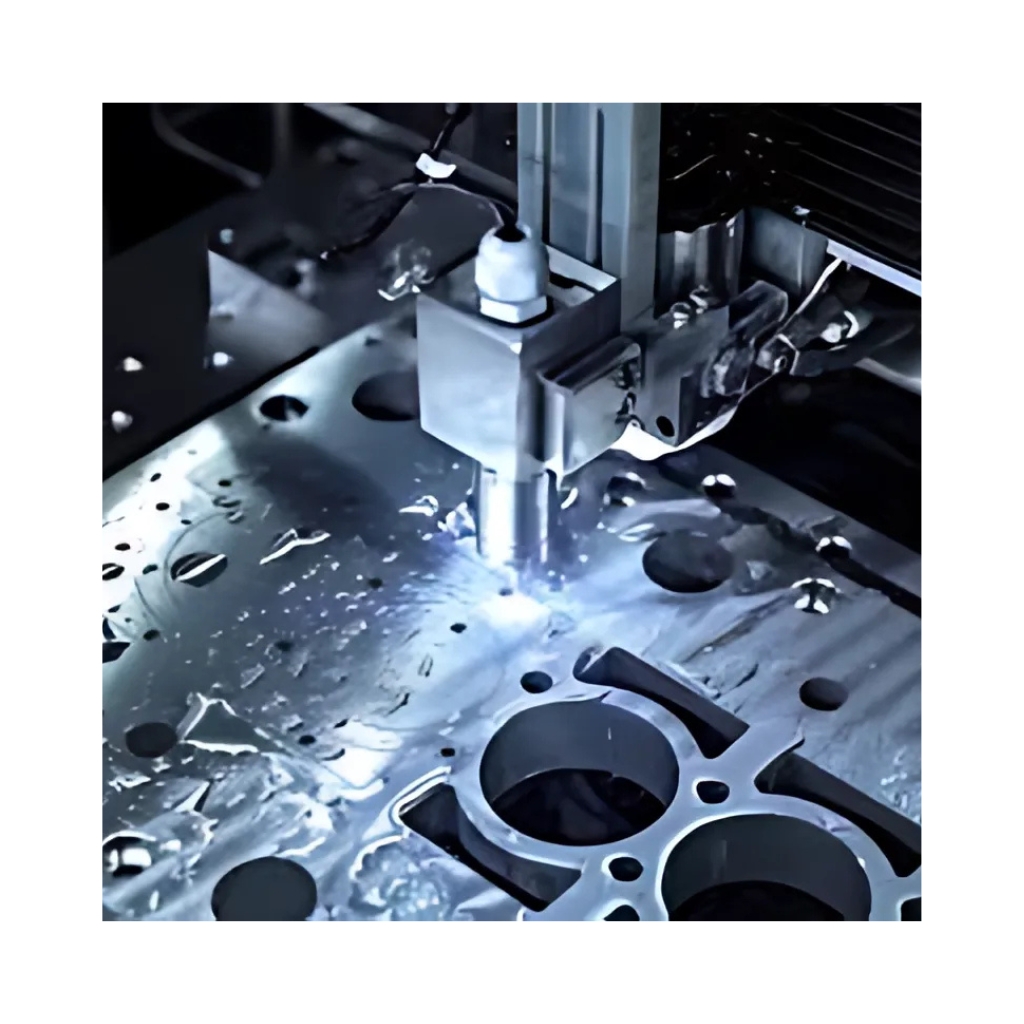

Toolroom

our Tool Room is more than just a manufacturing cell—it is the engineering heartbeat of our operations, enabling high-precision tooling solutions that drive quality, repeatability, and production agility across metal forming and fabrication.

In-House Tool Manufacturing: Full-spectrum tooling capability for forming dies , blanking tools, trimming fixtures, and fabrication jigs

Tool Maintenance & Refurbishment: Preventive and predictive maintenance programs ensure tool longevity and zero-disruption production

Precision Machining Infrastructure: Jig boring machine, wire-cut EDM, surface grinders, and high-accuracy milling machines

Rapid Tool Development Cycles: Seamless collaboration with design and engineering teams for fast turnaround of new tools and modifications

Prototyping

At VJS Auto Components, prototyping is not just a step—it’s a strategic enabler of innovation, customer collaboration, and market readiness. Our rapid and reliable prototyping function transforms concepts into tangible solutions with agility, precision, and design intelligence.

Rapid Part Prototyping: Quick turnaround of functional prototypes for metal components, assemblies, and tooling validation, Support for design iterations, form-fit-function analysis, and pre-series evaluations

Integrated Engineering Support: Close collaboration with design, tool room, and process engineers for seamless feasibility validation, application of DFM/DFA principles to ensure production-aligned solutions, soft tool setups and modular fixture design for agile trials

Our prototyping capabilities help bridge design intent and manufacturability empowering customers with clarity, speed, and production confidence.

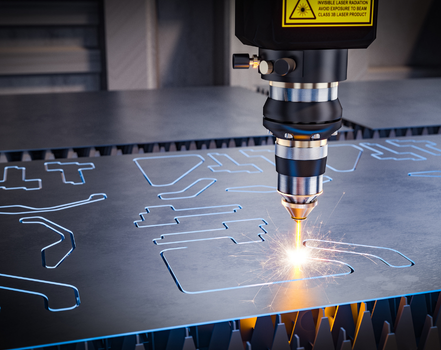

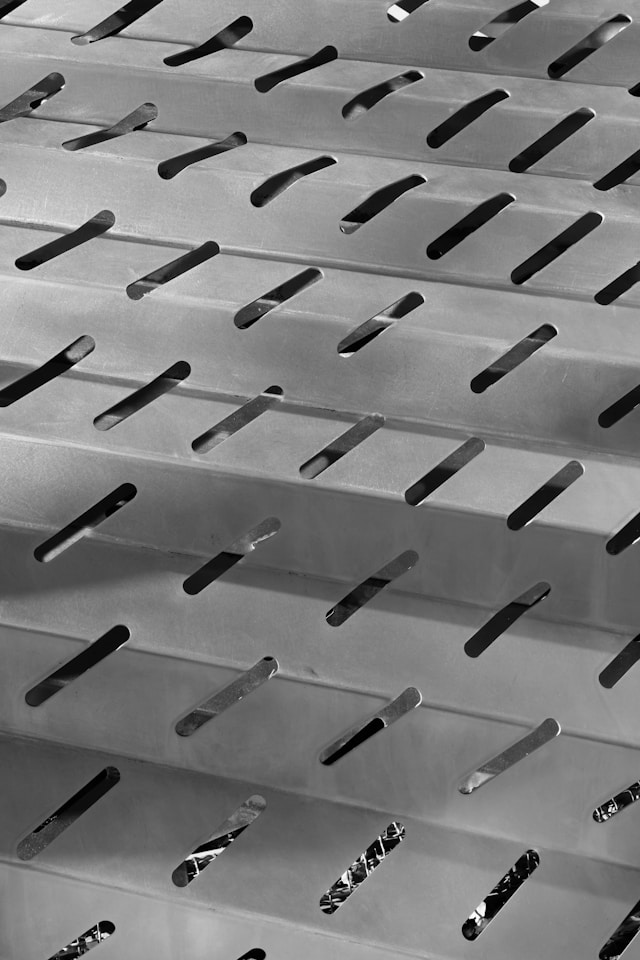

Stamping

our Stamping Facility is designed to deliver high-volume, high-precision metal components that meet the demands of modern automotive and industrial applications. Backed by robust infrastructure and deep tooling expertise, our stamping operations are the cornerstone of our manufacturing excellence.

Press Range & Capacity: Equipped with mechanical and hydraulic presses ranging from 40T to 400T for flexible production, supports deep draw, progressive, compound, and blanking operations across complex geometries

Tool & Die Integration: In-house die design and maintenance ensures tight control over quality, lead time, and process stability, seamless integration between stamping tools, jigs, and downstream fabrication

Material Versatility: Handles a wide range of materials including CRCA, HR, stainless steel, aluminium, and coated substrates, Material traceability systems ensure conformance to customer and regulatory requirements

From prototype to production, our stamping operations blend engineering rigor with manufacturing agility ensuring every part meets the highest standards of form, fit, and function.

Fabrication

our Fabrication & Assembly facility serves as a critical bridge between design intent and final product realization. Powered by advanced processes, skilled craftsmanship, and cross-functional integration, we deliver assemblies that are robust, reliable, and production-ready.

Metal Fabrication: Press brake, shearing, punching, and notching across sheet metal and structural parts, MIG/TIG/Spot welding operations with fixture-supported precision for consistent joins, specialized fabrication for brackets, housings, enclosures, and formed components

Mechanical & Structural Assembly: Modular assembly of sub-systems with mechanical fasteners, bushings, seals, and threaded inserts

Weld Fixture & Jig Support: In-house design and maintenance of custom fixtures to ensure repeatability and operator ergonomics, Process Poka-Yoke and lean layout for efficient part flow, Skilled welders, fabricators, and assembly operators with rich hands-on experience

Whether it’s a safety-critical structural weldment or a precision-machined bracket ready for integration, our fabrication and assembly line ensure form, function, and fit all delivered with trust and timeliness.

Painting

we take surface finishing to the next level with our state-of-the-art Powder Coating Facility, offering a premium, environmentally responsible alternative to solvent-based wet painting systems.

Eco-Conscious Technology: VOC-free and energy-efficient, our powder coating process supports clean, sustainable manufacturing practices

Superior Durability: Provides a tough, corrosion-resistant finish that withstands harsh environments and enhances product life

Aesthetic & Functional Excellence: Delivers consistent color, gloss, and texture across high-complexity parts—ideal for automotive, structural, and industrial applications

Advanced Surface Preparation: Multi-stage pre-treatment with a meticulous wash cycle ensures complete removal of oil, scale, and contaminants—right down to the bare metal

High-Volume Coating Line: Designed for speed, consistency, and precision—supporting a broad range of components with controlled film thickness

Quality First: In-line inspections, cure testing, and finish validation ensure every part meets stringent appearance and performance standards

From corrosion protection to enhanced brand appeal, our powder coating and surface finish solutions ensure your components look good and last longer with a footprint that respects the planet.

SEGMENTS

” We partner with Customers for Design, Manufacture & Assembling Industrial Products & Solutions, continuously moving up the value chain, by adopting Innovative, State of the Art Manufacturing Technologies, Systems & Processes, that are cost effective and functional “

Automotive

Farm Equipment

Construction

Electric Vehicle

Industries

Committed!

Always deliver more than expected.

Quality Statement here

Clients Love

Testimonial

Even the all-powerful Pointing has no control about the blind texts it is an almost unorthographic life One day however a small line of blind text by the name of Lorem Ipsum decided to leave for the far World of Grammar.

Subscribe For Newsletter

Sign up now for updates about early registration. A wonderful serenity taken possession into entire soul also like.